- Home Page

- Company Profile

-

Our Products

- Chain Pulley Block

- Carlstahl Chain Pulley Block

- Brad Chain Pulley Block

- Ferreterro Gold Chain Pulley Block

- Triple Spur Gear Chain Pulley Block

- Indef M Chain Pulley Block

- Indef P Triple Spur Gear Chain Pulley Block

- Morris Rs

- Stier S Pro Chain Pulley Block

- Ferreterro Silver Chain Pulley Block

- Morris Es

- Chain Pulley Block

- Geared & Push Trolley

- Electric Chain Hoist & Electric Trolley

- Electric Wire Hoist

- Anchor Plates

- Jib Crane

- Pallet Trucks

- Shackle

- Industrial Jacks

- Socket

- Winch

- Ratchet Buckles

- Ratchet Lashing

- Pressed Steel Hooks

- Bradys Material Handling Equipment

- Fittings

- Lashing Dee Shackle

- Large Dee Shackle

- Alloy Steel Bow Shackle

- ANCHOR SHACKLE

- Turn Bow Shackle

- Dee Shackle

- Crosby Bow Shackle

- Thimble

- Manila Rope

- Y Fitting

- Master Round Ring Assembly NON Welded

- Turn buckle Strainning Screw Type

- Stainless Steel D Shackle

- Misc Lifting Fittings

- Industrial D Shackle

- End Fittings for Side Curtains

- D Shackle

- Solid Thimbles

- Ms D Shackle

- Polyester Webbing Sling & Round Sling

- Drum Lifters

- PP Rope Slings

- Nylon Rope Slings

- Web Slings

- Polyester Webbing Sling & Round Sling

- Premium Slings

- Multi Ply Slings

- Endless Slings

- Reeving Choker Slings

- Heat Resistant Slings

- Round Slings

- Extreme Round Slings

- Eye and Eye Round Slings

- Two Path Round Slings

- Black Belt Slings

- Adjustable Bridle Slings

- Rotomaxx Slings

- Multilegged Slings

- Clover Leaf Slings

- Glass Handlers

- Pipeline Lifters

- Vertex Webbing

- Sleeves for Lifting Slings

- Dynaflexx Sling

- Chain

- Wire Rope Slings

- Hose

- Steel Wire Rope

- Wire Rope

- G.i.wire Rope

- Weight and Breaking Load as per IS-2266

- Powerform Compacted Rope

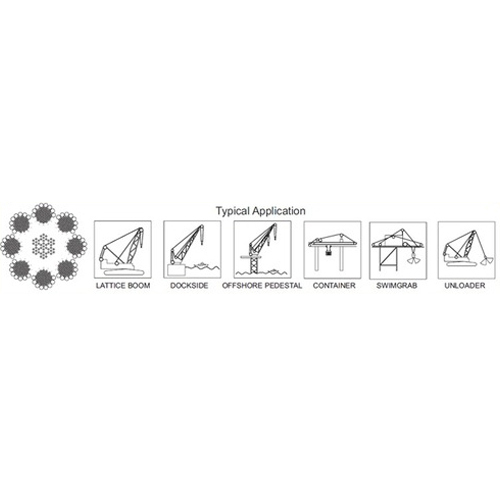

- Power Form 35 Wire Rope

- Hyflex 35 Wire Rope

- Power Form 18 Wire Rope

- HYFLEX 18 Wire Rope

- Power Form 6/6P Wire Rope

- Power Form 8/8P Wire Rope

- HYFLEX 8/8P Wire Rope

- Power Form 8PC Wire Rope

- HYFLEX 4 Wire Rope

- HYFLEX 6/36 Wire Rope

- HYFLEX 6/19 Steel Wire Rope

- HYFLEX 6/29 Fi Steel Wire Rope

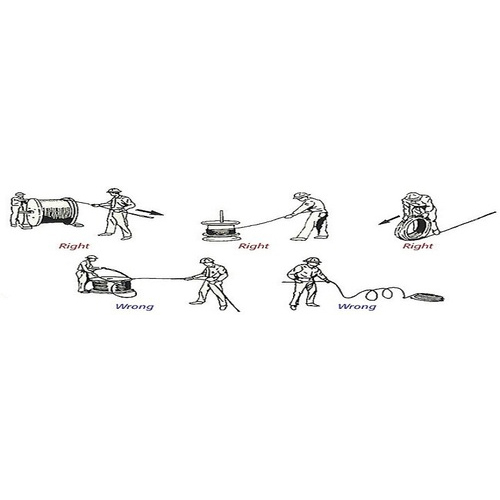

- Wire Ropes Storage

- Wire Rope 1x19 Stainless Steel Type 316

- Lifiting Tackles

- Pulling Lifting ( Hook Chook) Machines

- Lifting Tackles

- Forged U Clamp (Bull Dog Grip)

- Forged U Clamp

- Horizontal Plate Lifting Clamp

- Vertical Plate Lifting Clamp

- Beam Clamp

- Lifting Accessories

- Chain Wheel

- Eye Hook for Wire Rope Application

- Round Ring NON Welded

- Round Ring WELDED

- Web Connecting Link

- Oblong RIng WELDED

- Master Oblong Ring Assembly WELDED

- Coonecting Link

- Chain Shortner

- Oblong RIng NON Welded

- Alluminum Feerule

- Ordinary Thimble

- Solid Thimble

- Turn buckle Bottle Screw Type

- M.S. Eye Bolt

- High Tensile Eye Bolt

- Cable Puller

- Chain Sling

- Delta Rings

- Wire Hooks

- E.O.T Cranes

- Snap Hooks

- Industrial Hook

- Stainless Steel Anchor

- Anchor Chain

- Pulley

- Electric Chain Hoist

- Eye Bolt

- Ratchet Lever Hoist

- Pulling Lifting Machine

- Chain Pulley Block

- Contact Us

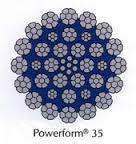

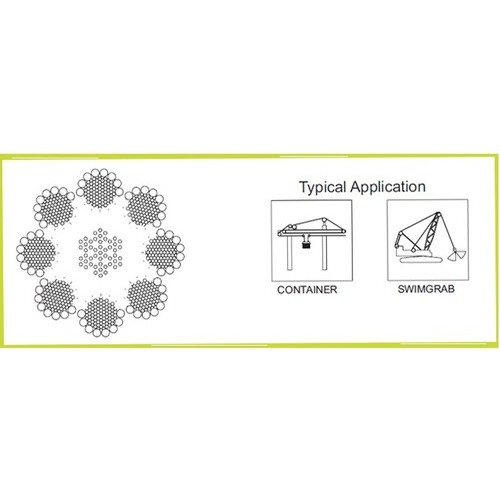

Power Form 35 Wire Rope

Product Details:

- Product Type Wire Rope

- Material Galvanized Steel

- Alloy Stainless Steel

- Application Binding Construction Machinery Packaging Fencing Rope Industry Kitchen Transportation Fishing

- Wire Diameter 2-32 Millimeter (mm)

- Length 50 Meter (m)

- Color Silver

- Click to View more

X

Power Form 35 Wire Rope Price And Quantity

- 1 Piece

Power Form 35 Wire Rope Product Specifications

- Stainless Steel

- Silver

- Wire Rope

- Binding Construction Machinery Packaging Fencing Rope Industry Kitchen Transportation Fishing

- 2-32 Millimeter (mm)

- 50 Meter (m)

- Galvanized Steel

Power Form 35 Wire Rope Trade Information

- Cash in Advance (CID) Cash Advance (CA)

- Per Month

- Days

- Western Europe Australia Middle East Central America Africa South America Asia Eastern Europe North America

- All India

Product Description

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS